Reinforced concrete structures

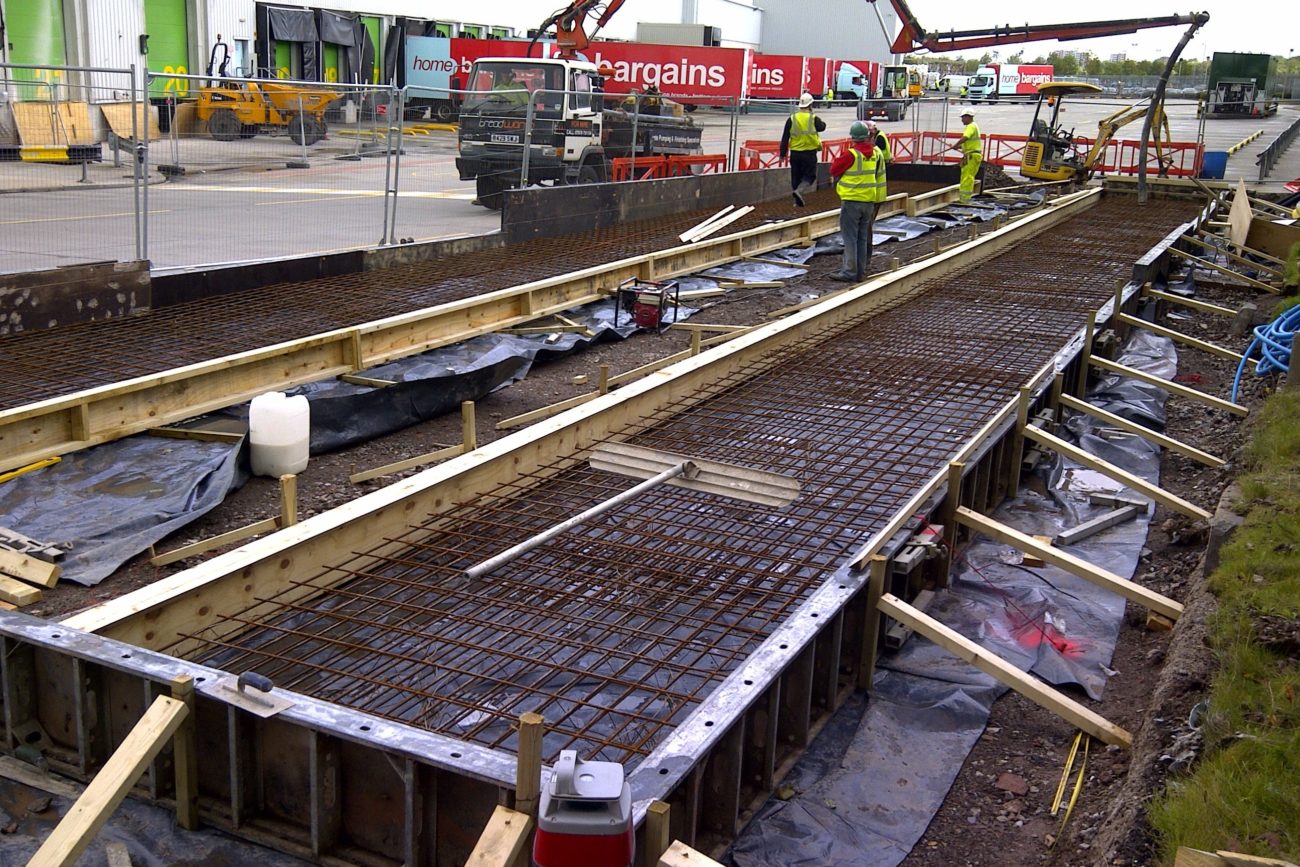

DXI have completed numerous reinforced concrete structures including :

• Concrete terracing for stadiums

• Sweeper bays in operational HWRC facilities

• Wheel wash pits in operational logistics depots

• Push wall in operational HWRC facilities

• Foundations for weighbridges

• Water retaining structures

• Turbine bases & sub-station foundations

We have also completed several reinforced concrete floor repair contracts in operational HWRC facilities were traffic flows cannot be interrupted and areas of work are sectioned accordingly.

DXI are renowned for their accommodating approach to clients who operate in a 24 / 7 environment and often undertake works at off peak times.

Geographically, we have completed projects in Kent and the midlands as well as Holyhead, Anglesey.

CLIENT

FCC Environment Ltd / Veolia

REFERENCE CONTACT

WSP / QualSurv Project Services / FCC Environment

CONTRACT VALUE

£2.53Million (cumulative)

CONTRACT DETAILS

Stadium seat terracing, Sweeper bays, Wheel wash pits, Push walls